The convenient, efficient and reliable DA-800 series is KEM’s (Kyoto Electronics Manufacturing Co., Ltd.) 6th generation line of density/specific gravity meters, inheriting technology developed with market needs firmly in mind.

InquiryPRODUCT

Density/Specific Gravity Meter

DA-860/850/840

Features

The DA-800 series density meters measure the density/specific gravity of liquid samples by employing an oscillating sensor to determine resonant frequency. What’s more, the instruments can calculate sample concentration according to common industry standard formulas and tables.

The instruments have a built-in temperature stabilizing function, allowing you to measure density/specific gravity at your desired temperature.

Measurement can be conducted with as little as 1mL of sample (if injected manually), and in as fast as 10 seconds for a temperature-stabilized sample (when viscosity correction is disabled). All models in the DA-800 range come with viscosity correction functionality as standard.

Data Integrity (DI) support functions are provided as standard to help you maintain and manage your valuable data.

The interface has been enhanced to support a variety of uses, such as a separate structure for the operation unit (tablet/PC) and measurement unit, wireless LAN connection, and connection of multiple units.

The instrument has a space-saving design and can be integrated with a semiautomatic cleaning unit (optional). Also included is a camera for viewing inside the measurement cell, improving reliability, convenience, and efficiency.

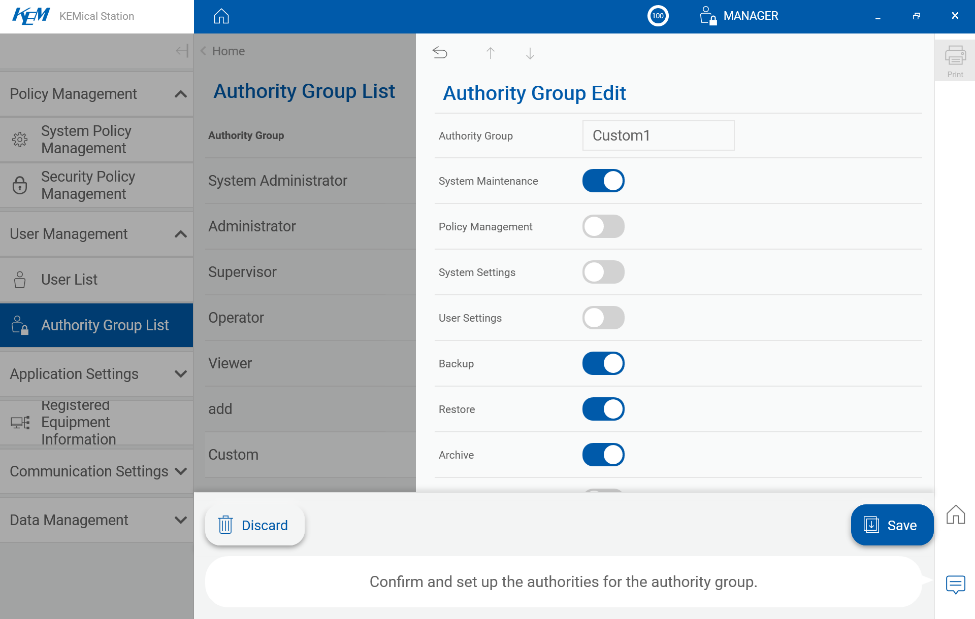

・DI support functions are included as standard

The following features are included as a standard for Data Integrity.

・User authentication : Authentication by personal ID and password is possible.

・Authority management: Possible to set authority such as editing restriction by personnel.

・Audit trail: Possible to automatically record operating history.

・Digital signature: Possible to perform electronic certification and digital signature by workflow.

・Back up/Restore/Archive: Automatic back up function in every optional period.

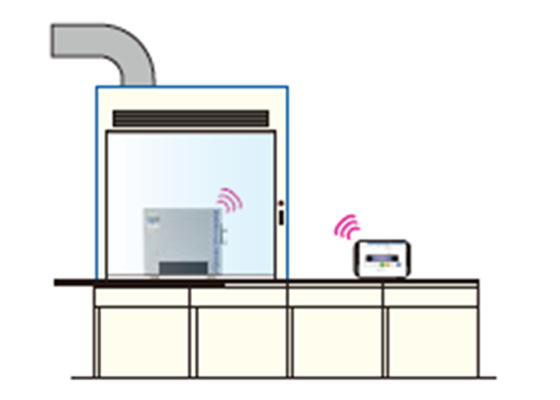

・Separate operation unit and measurement unit

・The measuring unit can be placed in a fume hood and operated remotely from outside the fume hood.

・The unit can be operated remotely from a separate location via a wireless LAN connection (optional).

・Semiautomatic cleaning unit

・The semiautomatic cleaning unit (optional) is a space-saving design integrated into the measurement unit and enables automatic measurement including drainage, washing, and drying.

- High reliability

1) KEM is the only manufacturer in Japan of standard liquids that conform to ISO17034, which is traceable to national standards.

2) KEM oscillation-type density meters are calibrated with international MRA*1-compliant and ISO17025-compliant JCSS*2 laboratory

density standards, which are traceable to international standards in the world.

*1 Mutual Recognition Arrangement

*2 Japan Calibration Service System

3) High accuracy (DA-860: 3×10-6 g/cm3)

High repeatability (DA-860: 1×10-6 g/cm3)

High reproducibility (DA-860: 2×10-6 g/cm3)

- Equipped with a camera for viewing the measurement cell

1) Improved visibility of the measurement cell.

2) Image inside the measurement cell at the end of measurement can be saved to check the sample status.

- Short measurement time

1) The new stability mode developed by improving the conventional algorithm was added to shorten the measurement time.

2) The shortest measurement time is approx. 10 sec when the temperature is stable.

- Multiple management by a single operation unit

Multiple measurement units (max. 4 units) can be operated simultaneously by a single operation unit and the data can be managed comprehensively. (optional)

Applications

The instrument can be used for liquid concentration control and quality control in the following segments.

- Determination of transaction prices and taxes for crude oil and petroleum products (fuel oil and lubricants)

- Purity control and quality control of substances produced by chemicals (chemical products)

- Brix measurement as production process control and quality inspection for milk products, carbonated drinks, fruit drinks, etc.

- Measuring the concentration of alcohol and extracts in beer, sake, wine, etc.

- Brix concentration measurement of sugar solution, syrup solution, isomerized sugar solution, seasoning, etc.

- Pharmaceutical Densitometry Based on Pharmacopoeia

- Quality control of oils and fats such as vegetable oils and animal oils

- Quality control of flavors, chemicals, etc.

- Quality control of surface treatment agents such as etching solution and acid cleaning solution

Specifications

| Type | Density/Specific Gravity Meter |

|---|---|

| Model | DA-860/850/840 |

| Measurement Method | Resonant frequency oscillation |

| Measurement Range | 0 to 3 g/cm3 |

| Temperature Range*1 | 0 to 100°C (32 to 212°F) |

| Accuracy | Density*2:

DA-860: 0.000003 g/cm3 DA-850: 0.00001 g/cm3 DA-840: 0.00005 g/cm3 Temperature: DA-860:±0.02℃ (±0.04° F) DA-850:±0.03℃ (±0.05° F) DA-840:±0.05℃ (±0.09° F) |

| Repeatability*2 | Density:

DA-860: 0.000001 g/cm3

DA-850: 0.000005 g/cm3 DA-840: 0.00005 g/cm3 |

| Reproducibility*2 | Density:

DA-860: 0.000002 g/cm3

DA-850: 0.000005 g/cm3 DA-840: 0.00005 g/cm3 |

| Interfaces | LAN, USB, RS-232C |

| Power Supply | AC100 to 240V; 50/ 60Hz (Comes with AC adapter) |

| Power Consumption | 40W (max. 120W, min.20W) |

| Dimensions | 295 (W) x 330 (D) x 255 (H) mm (11.6 (W) x 13.0 (D) x 10.0 (H) inches) |

| Weight | 19 kg (42 lbs) |

*1: The above accuracy is guaranteed in the temperature range of 0 to 90°C with all series.

*2: According to ISO 5725 under ideal conditions.

Standards

ASTM D1250 Standard Guide for Use of the Petroleum Measurement Tables

ASTM D4052 Standard Test Method for Density, Relative Density, and API Gravity of Liquids by Digital Density Meter

ASTM D4806 Standard Specification for Denatured Fuel Ethanol for Blending with Gasolines for Use as Automotive Spark-Ignition Engine Fuel

ASTM D5002 Standard Test Method for Density, Relative Density, and API Gravity of Crude Oils by Digital Density Analyzer

ASTM D5931 Standard Test Method for Density and Relative Density of Engine Coolant Concentrates and Aqueous Engine Coolants by Digital Density Meter

European Pharmacopoeia / 2.2.5. RELATIVE DENSITY

ISO 12185 Crude petroleum and petroleum products -- Determination of density -- Oscillating U-tube method

ISO 15212-1 Oscillation-type density meters -- Part 1: Laboratory instruments

JIS K0061 Test methods for density and relative density of chemical products

JIS K2249-1 Crude petroleum and petroleum products -- Determination of density -- Part 1: Oscillating U-tube method

JIS Z8804 Methods of measuring density and specific gravity of liquid

OIML R 22 Traceability and computerization of alcoholometric tables

United States Pharmacopeia–National Formulary / 31 <841> SPECIFIC GRAVITY

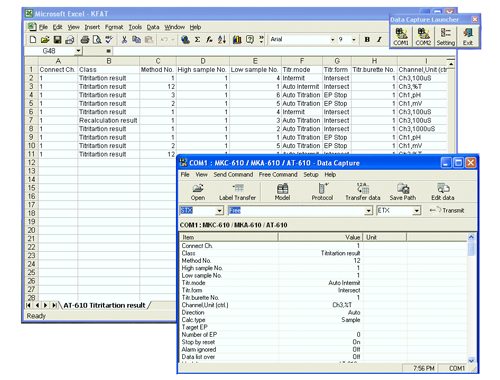

Software

Option

-

JCSS Accredited Density Standard Liquid

Used to confirm the measurement accuracy of oscillation-type density/specific gravity meters in routine checks and calibrations.

KEM’s range of standards can be used for testing density in the range of 0.69***g/cm3 to 1.49***g/cm3 (at 20°C). -

Auto Sampler

AS-8030

The autosampler AS-8030 is developed with the improvement in convenience and efficiency to meet market demands, inheriting reliability and technology established over many years, by Kyoto Electronics Manufacturing Co., Ltd. (KEM).

-

Multiple Sample Changer

CHD-502N

30 samples can be loaded for continuous measurements.

Pressurized sampling by pump.

Room temperature only. -

Multiple Sample Changer (High temperature model)

CHD-502H

This equipment automates continuous measurement of viscous test materials by heating electrically to determine their density or specific gravity in sequence with your Density/specific gravity meter, performing rinsing and purge drying the measuring cell and sampling line as well.

-

Auto Clean and Sampling Unit

DCU-551N

Automatic sample delivery and cleaning for the measurement of single sample at room temperature.

Sample vial: 20mL. -

Auto Clean and Sampling Unit(High temperature model)

DCU-551H

This equipment automates continuous measurement of viscous test materials by heating electrically to determine their density or specific gravity in sequence with Density/specific gravity meter, performing rinsing and purge drying the measuring cell and sampling line as well.

Catalog

■General-Catalog.pdf

■Density Specific Gravity Meter DA-860 850 840.pdf