The Niizawa Sake Brewery established its headquarters in 1873 (the 6th year of the Meiji period) in Ōsaki, Miyagi Prefecture. Sadly, the brewery suffered irreparable damage in the Great East Japan Earthquake of March 11, 2011, which inspired the decision to make a intraprefectural relocation, establishing a new production facility in Kawasaki Town, Shibata District in the same year.

Later in 2013, their head office would also be completed. It is not difficult to imagine the tremendous hardships endured and the turbulent journey that has led to the present day. Also in 2013, Niizawa adopted our SDK system (for alcohol content measurement) and automatic potentiometric titrator (for measuring total acidity and amino acid content).

In this edition of In the Field, we are pleased to be interviewing Mr. Iwao Niizawa, 5th Generation Chief Brewer & Company President. With his passion for sake brewing, fresh approach, and formidable drive, he not only coined the term shokuchū-shu (sake to accompany a meal) at a time when only aperitif and digestif were recognized, but also created an entirely new category of sake which remains championed by the company to this day.

COLUMNIn the field

Alcohol Analysis of Sake at Niizawa Brewery Co.

An innovative sake brewery unconstrained by conventions: we speak with Mr. Iwao Niizawa of Niizawa Sake Brewery, producer of Hakurakusei, the ultimate sake for pairing with food.

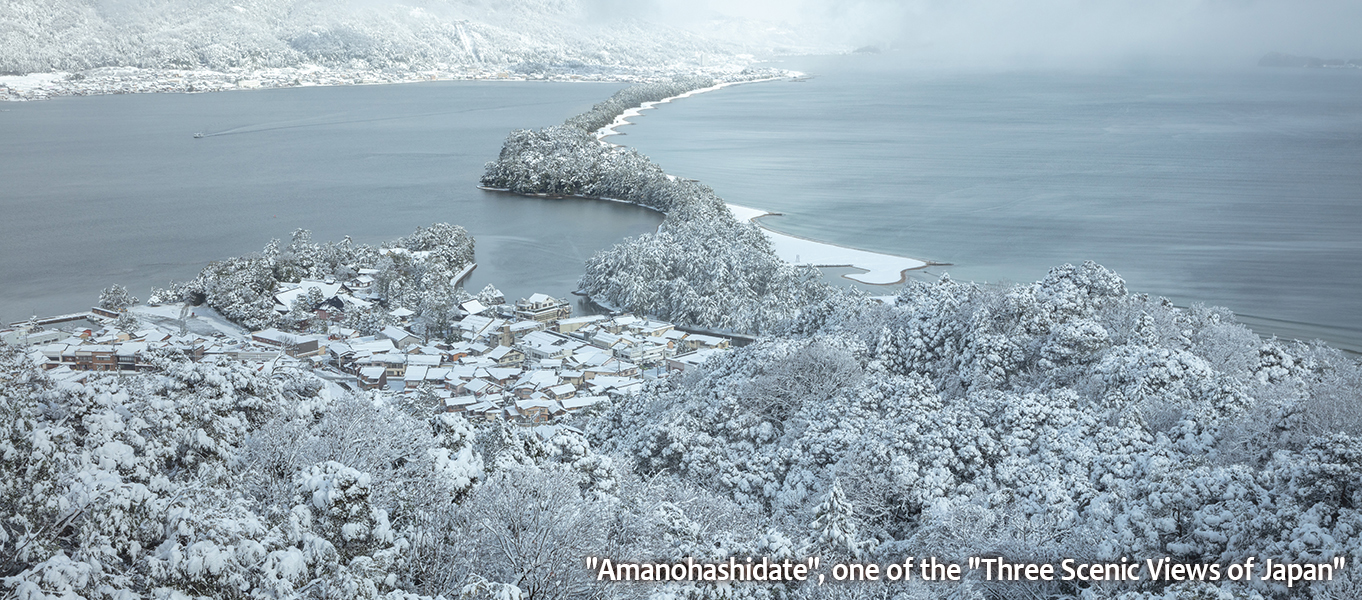

The brewery surrounded by snow in winter.

Kawasaki, Miyagi Prefecture.

Niizawa Sake Brewery 5th Generation Chief Brewer & Company President, Iwao Niizawa

A brewery employing cutting-edge technology to foster the growth and evolution of its sake artisans, overturning the traditional image of sake making.

The youngest woman to become a Head Brewer, Nanami Watanabe and Assistant Head Brewer, Sam Callon.

A commonly held image of the sake maker’s grueling work life depicts “a commitment to work, eat, and sleep at the brewery over the cold winter production period, waking in the dark preceding the sun’s rise each morning to commence draining manual labor-suitable only for the most dedicated”. Though this image may involve a little exaggeration, Niizawa nonetheless intends to do all it can to turn this image on its head.

Niizawa is assertive in adopting cutting-edge brewing tech to eliminate the requirement for intense labor to the furthest extent possible, while simultaneously creating an environment conducive to managing the greatest standards of quality. Not only has this resulted in great products, but it has also allowed them to assign work shifts of lengths that don’t differ from those of your standard company type. It’s a welcome surprise seeing how much sake making has evolved, especially with regard to the ground-breaking improvements in employee welfare.

Speaking of which, Niizawa’s support is not limited to the workplace, the business also provides one year of free dormitory accommodation, subsidizes the purchase of a private car, and provides other forms of financial assistance so staff spend less time worrying about living expenses and arrangements, and focus on devoting themselves to learning and engaging with the art of sake brewing.

And it appears to be paying off, because a star has been born in the form of one, Nanami Watanabe, who works as Head Brewer, achieving this rank at a record young age among other female brewers nationwide. Watanabe won top honors at the Concours Mondials de Bruxelles (CMB) SAKE selection 2018, taking home the Platinum Trophy in the Honjozo category, proving that she is not only a young leader in name, but in deed too.

So, just what advantages has the adoption of KEM instruments brought...?

KEM:

What advantages has the adoption of KEM instruments given to your lab?

President Niizawa:

I can think of at least 4 right off the bat. Firstly is our ability to get consistently accurate results, thanks to their reliable performance. Secondly, is our successful achievement of automation. This has resulted in use gaining accurate results without the need for human intervention. The third advantage is increased analysis speed. In other words, we have been able to speed up the process covering all steps from sampling to data acquisition.

It used to be that mornings were devoted to the management and preparation of brews, so analyses could only begin in the afternoon once our hands were free. Even at the earliest, analysis results were available only by the evening, meaning adjustments to the moromi mash could not be made until the following day. If samples are loaded into our automated analysis system in the morning, all results are available by noon, allowing us to make adjustments to the mash in the afternoon. Truly, we were working flat out to complete manual analysis once every 2 days, but now we get data every day allowing daily batch adjustments. You can liken moromi mash to a living creature, its condition changing moment to moment. The longer it takes to make adjustments to it, the more difficult it becomes to control the final result. The fourth advantage is the surplus of energy in our sake makers. Time and labor-saving automation allows staff to dedicate their energy to batch adjustments and the analysis of sample parameters aside from alcohol content.

KEM:

Certainly sounds like there any many benefits to adopting our analysis system! I trust it is also helping in maintaining product quality?

President Niizawa:

Yes. And on top of that, it frees up time and lowers costs thanks to us being able to tackle batch adjustment faster.

KEM:

We are beyond happy to hear of the numerous advantages our analysis system is bringing. As a matter of fact, the development team’s decision to make the SDK System’s autosampler accommodate 20 samples was inspired by a request by yourself.

President Niizawa:

That’s right. The production process of many small- to mid-size sake breweries such as ours, works on the hanjimai method, in which one batch is started every two days. For this, 6 shubo (yeast starter) tanks, 12 moromi tanks, and 1-2 finished product tanks are subject for sampling. This is my rationale for requesting a changer accommodating 20 samples.

KEM:

Your request made perfect sense to our tech developers, leading to its adoption in making the sampler. Thanks to this, KEM was able to realize an analysis system optimally catered to the industry, contributing tremendously to its adoption by hundreds of domestic sake breweries. So it was only natural that the momentous occasion of installation of the very first next generation autosampler occurred at your brewery. We would like to take this chance to kindly thank you once again.

President Niizawa:

I am very welcoming to products that grant so many advantages. You are more than welcome to send any new prototypes our way if you need someone to test them out in the field for you (haha).

KEM:

We are certainly glad for the offer! Thank you. Well, then, thank you once more for your time and telling us about your business. We look forward to supporting you into the future.

Editor's note: The original Japanese language interview was first published in 2021.