Brewed beverage is roughly classified into two types depending on used ingredients. Typically, brewed beverage fermented from fruit is wine and that fermented from grain is beer and sake. Grain, having good keeping quality and being fully available for transportation, is an important ingredient for sake brewing, however, as I introduced in the previous issue, especially, “water” is the other important ingredient. Matsumoto Sake Brewing, being convinced of the importance of water prepared for brewing, moved their brewery to “Fushimi”, south of Kyoto city. The name of “Fushimi” expresses “lying down water”, there is huge amount of good quality groundwater. They inspected the location and carried out the relocation plan. They inaugurated the brewery named “Daikoku-kura”, in 1925 (Taisho 14, Taisho is the Japan’s imperial era name). Another main reason why they chose the location was the town’s name. There are the seven deities of good fortune who are worshiped since ancient times. They, called Ebisuten, Daikokuten, Fukurokuju, Bishamonten, Hotei, Juroujin and Benzaiten, have been passed down with the history of cultural exchange between India, China, Asia and Japan and worshiped from the Muromachi period to today. Southern area of the brewing building is called Daikoku-cho derived from Daikokuten who has a bale of rice, eastern area is called Ebishu-cho derived from Ebisuten who holds a sea bream. They built the brewing building on that location where they felt something familiar to prosperous business and good harvest.

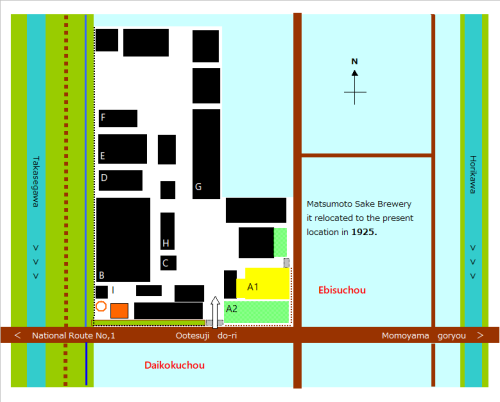

[fig.1]Facility map of Matsumoto Sake Brewing Co., Ltd.

(Site area: 20,000 m2, 18 buildings)

Entering from Otesuji street through the front gate, immediately on the right side, there is “Mangyouin” (A1 and A2) with a Kyoto style garden surrounded by trees. A wooden brewery (G) on the front was relocated and reconstructed from the old one in Shichijo, Kyoto city. On the left side of the square, an office (C) is located. A Daikoku-kura (B) is located at the back. Additionally, a refrigerated warehouse (E) and a rice mill (F) are located.

A1: Mangyouin: guest house for the brewery.

A2: Kyoto style garden

B: Daikoku-kura: brewing building

C: Reception of the office

D: Product bottling building

E: Product Refrigerated warehouses

F: Rice mill plant

G: Old brewery

H: Laboratory

I: Boiler: Brick chimney

After they decided the relocation, they dug several wells as the first work to do. Even now, there remain seven wells on-site.

On-site: One of wells, named “Daikoku-well”, is located on the middle between brewing building and brick building, and is used for water prepared for brewing

Let’s see the on-site arrangement and structure of the brewing building, “Daikoku-kura”. It has the excellent operability and the most reasonably completed style as wooden Sake brewing building.

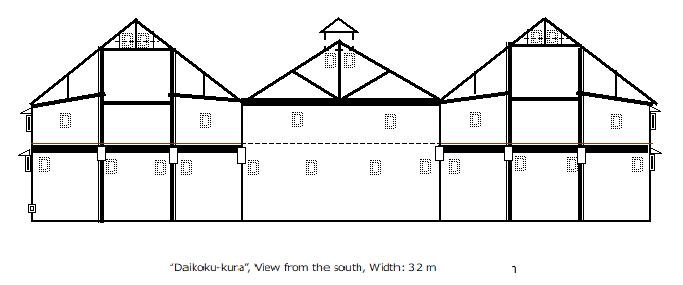

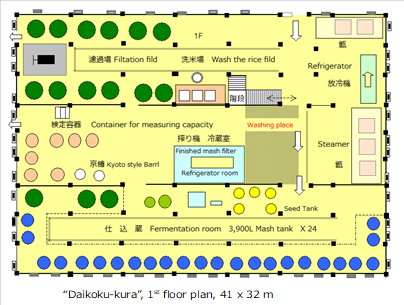

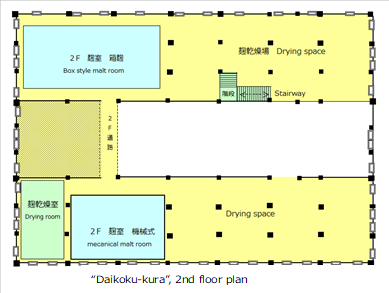

The “Daikoku-kura” is composed of three joined buildings. The left and right buildings are designed in Japanese style and the middle building is designed in Queen Post Truss style. The middle building has an open ceiling space without pillar nor second floor to let out steam from the traditional steamer to exhaust port at the ceiling called “Garari”, the dirt floor is well devised for dehumidification and ventilation in order to rinse and sterilize tools and instruments there.

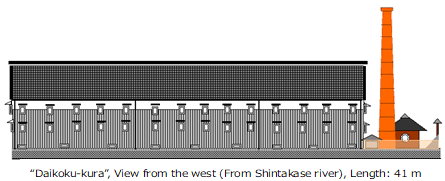

In Sake brewing, “Kanzukuri (cold brewing)” style which perfected around the later Edo period has been passed down in a fundamental way. White rice, a raw ingredient, is washed by clean water, absorbed moderate amount of water, drained the water, steamed in the steaming basket. Then, it is cooled down to the temperature depending on the purpose by clean cold air of winter. For that process, the building has the well thought out ideas. One is the windows installed near the dirt floor to take in external air, and the other is the ventilation windows in line near the first floor ceiling and upstairs floor. The base surrounding building is firmly made by piling up six layered stone bars (L200 × W30 × H40cm per stone) and using underground beams. The upper part of the wall is painted white by plaster, taking contrast of scenery into consideration, the “Charred cedar” planks of 18 centimeters thick are laid on the side wall, considering practical uses to withstand long lasting rain in rainy season and typhoons in autumn.

COLUMNEssay

Essay

Scenery from the sake brewery - 002 Arrangement and structure of sake brewery

Monthly photo essay on Japanese sake brewing by Mr. Keiichiro Katsuki, a Japanese sake brewing expert.

Please refer to episode 001 for more information on the author.